Quality B cleanrooms are utilized for aseptic planning, filling, and compounding procedures. They're similar to ISO Class five cleanrooms at relaxation and ISO Class seven cleanrooms in Procedure.

The needed degree of cleanliness for the Quality A area is received using a laminar flow cabinet or perhaps a laminar airflow hood (LAF). In the event the bordering air is preserved and classed as Grade B, a laminar movement cabinet can attain a cleanliness classification of Quality A.

e Sample assortment constraints for the two particles in very low concentrations and dimensions bigger than one μm make classification at this particle measurement inappropriate due to opportunity particle losses during the sampling system.

Comprehension the GMP requirements as well as their grades could be hard sometimes, In particular with various regulatory bodies in other nations around the world. What tend to be the variations amongst a Quality A, Grade B, Grade C, or Quality D cleanroom atmosphere? This article will protect:

Class a hundred cleanrooms are available in a broad assortment of models and configurations that modify based on the producer. Softwall and hardwall cleanrooms are The 2 fundamental kinds and the ones which might be most often made use of.

The filter method is meant to remove particles and contaminants within the air supply. Integrity tests will involve assessing whether or not the filters are properly installed, freed from leaks, and effective at correctly trapping particles.

Grade C cleanrooms are used for significantly less significant levels within the manufacturing procedure. They find purposes in the next actions:

Chemicals and compounds that fulfill these expectations allow makers to develop medication with consistent high quality, effectiveness, and purity.

Opt for a site from resources of contamination such as dust, industrial pollutants, or large site visitors areas.

(a) To get to the B, C, and D air grades, the number of air alterations really should be relevant to the dimensions of the home plus the products and staff existing within the space. The air process need to be provided with suitable filters like HEPA for grades A, B, and C.

The here greatest menace to cleanroom contamination emanates from the users on their own.[18] During the Health care and pharmaceutical sectors, Charge of microorganisms is vital, Specially microorganisms likely to be deposited into your air stream from pores and skin shedding.

Cleanrooms Engage in a important role in preserving the integrity and excellent of products and solutions in many industries. The classification program, starting from Class 100 to Class one thousand and outside of, provides a standardized framework for defining cleanliness expectations and ensuring compliance with marketplace specifications.

3 micron and larger in measurement. Most of the air shipped to a cleanroom passes via HEPA filters, and in some instances the place stringent cleanliness general performance is necessary, Extremely Small Particulate Air (ULPA) more info filters are used.

The containment leak check evaluates the usefulness of actions in place to consist of contaminants inside the cleanroom. This is very significant in amenities in which hazardous or potent resources are dealt with.

Lark Voorhies Then & Now!

Lark Voorhies Then & Now! Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Yasmine Bleeth Then & Now!

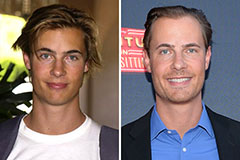

Yasmine Bleeth Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Sarah Michelle Gellar Then & Now!

Sarah Michelle Gellar Then & Now!